3-Kanal 2.4GHz RC ferngesteuertes Segelflugzeug, optional erweiterbar mit Kamera, Modellbau Glider, Spannweite von 750mm, Flieger-Modell mit EPO-Material, Komplett-Set inkl. Akku und Fernsteuerung: Amazon.de: Spielzeug

Suchergebnis Auf Amazon.de Für: Ferngesteuerte Flugzeuge - 100 - 200 EUR / Ferngesteuerte Flugzeuge / App- & Fer...: Spielzeug

3-Kanal 2.4GHz RC ferngesteuertes Segelflugzeug, optional erweiterbar mit Kamera, Modellbau Glider, Spannweite von 750mm, Flieger-Modell mit EPO-Material, Komplett-Set inkl. Akku und Fernsteuerung: Amazon.de: Spielzeug

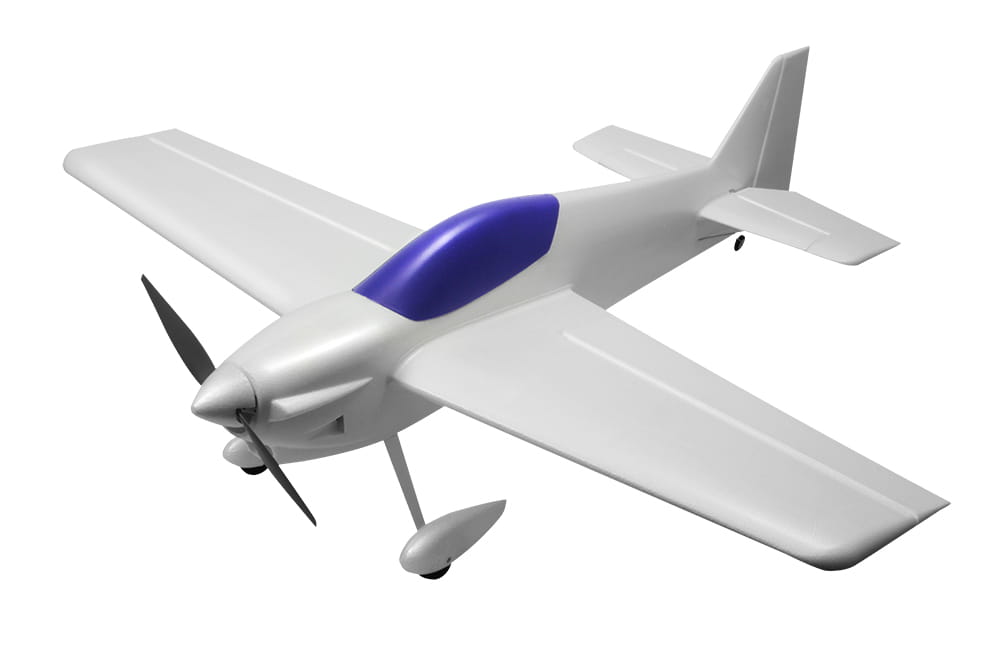

Amewi AMEWI AMXPlanes P68 850mm Elektromotor Hochdecker PNP blau buy online at Modellsport Schweighofer