1994 Porsche 964 3.6 Turbo- Amazon Green over Cashmere, $15k in service just completed, all original and 27k miles. Is there an air-cooled car that causes more lust than this? - Columbia

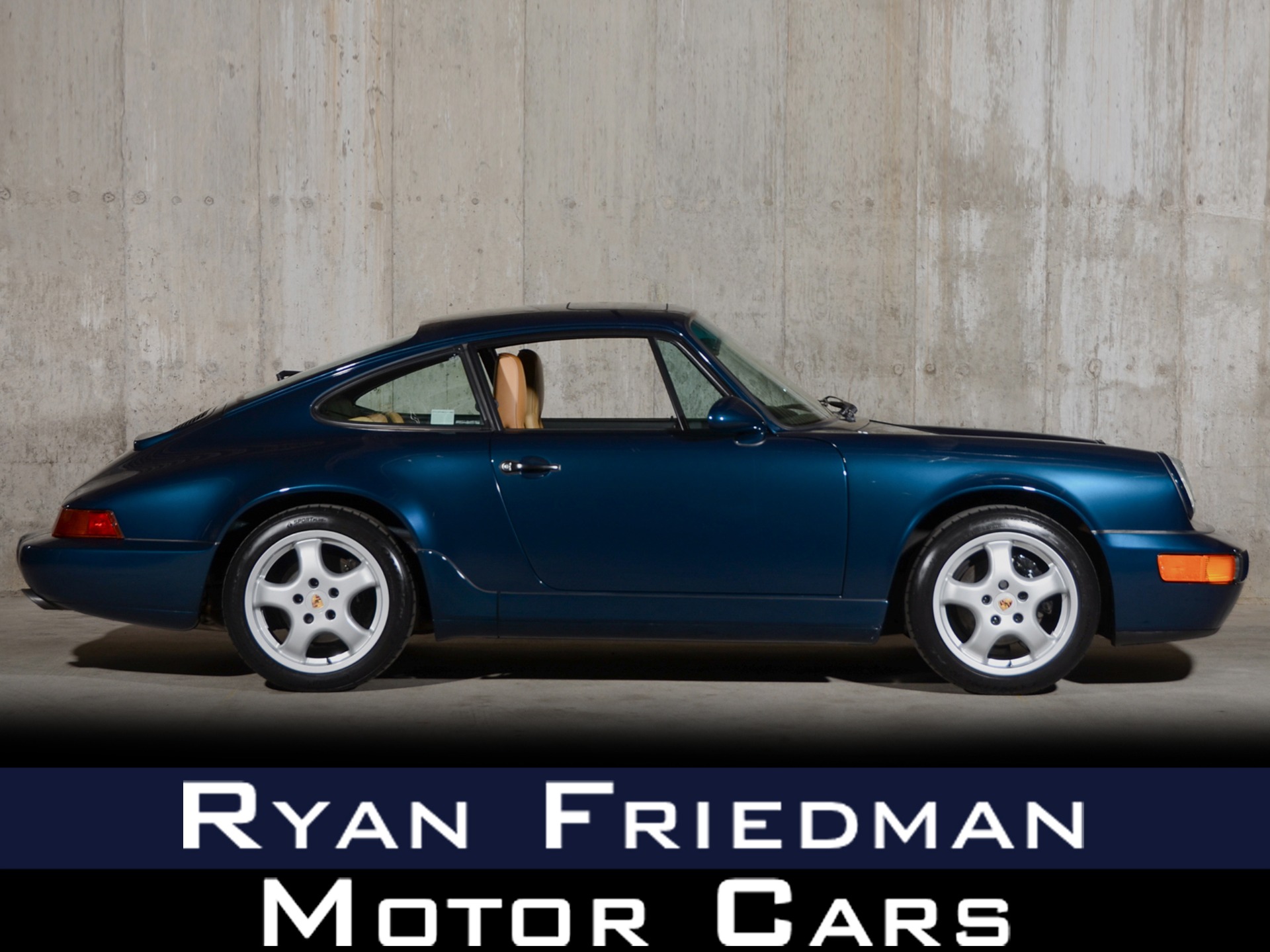

1993 Porsche 911 964 Carrera 2 Rare 1 of 505 US Coupes/ Amazon Green /5 Speed Manual /Limited Slip Differential - RMCMiami

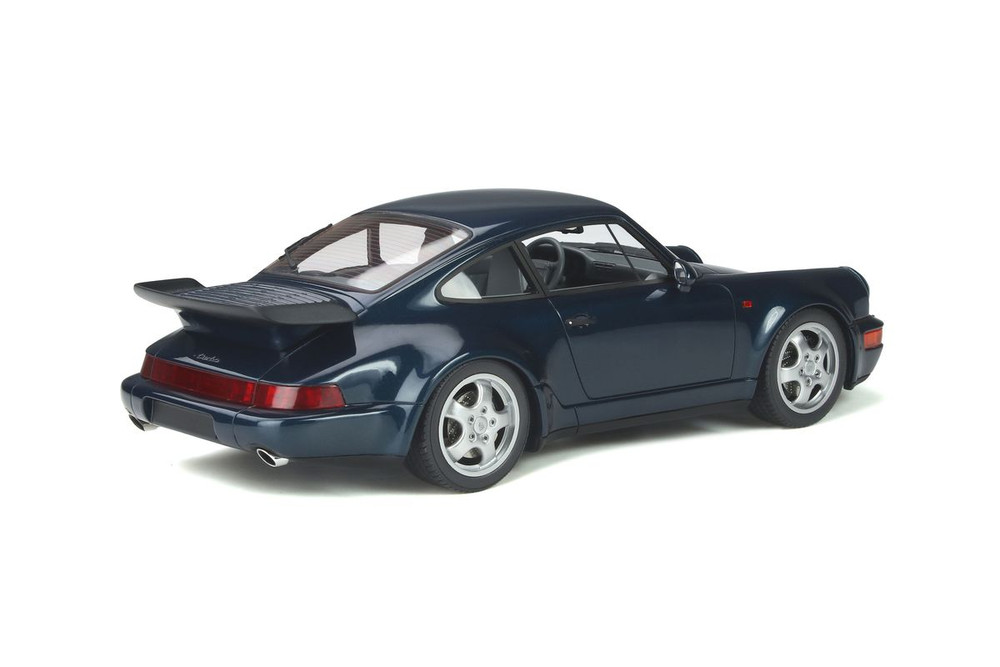

1991 Porsche 911 (964) Turbo 3.3 Hardtop, Amazon Green - GT Spirit GT315 - 1/18 scale Resin Model Toy Car - Walmart.com

1991 Porsche 911 Turbo for sale on BaT Auctions - sold for $196,000 on September 18, 2022 (Lot #84,752) | Bring a Trailer

1991 Porsche 911 (964) Turbo 3.3 Hardtop, Amazon Green - GT Spirit GT315 - 1/18 scale Resin Car - ModelToyCars.com

Amazon.com: TOKAXI 1/36 Scale Porsche 911 Trubo Diecast Car Models,Pull Back Vehicles Porsche 911 Toy Car,Cars Gifts for Boys Girls : Toys & Games

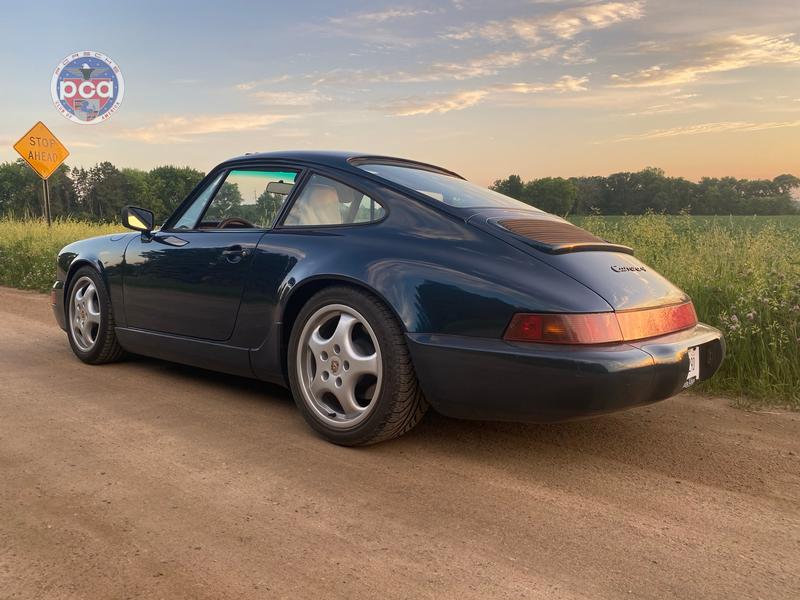

1993 Porsche Carrera 4 Coupe - Gorgeous Amazon Green and Well Maintained - Rennlist - Porsche Discussion Forums

1992 Porsche 911 Turbo for sale on BaT Auctions - sold for $210,000 on July 3, 2023 (Lot #112,376) | Bring a Trailer

1993 Porsche 911 964 Carrera 2 Rare 1 of 505 US Coupes/ Amazon Green /5 Speed Manual /Limited Slip Differential - RMCMiami

Amazon.com: KiNSMART Porsche 911 GT3 RS 1:36 Scale 5inch Die Cast Model Toy Sports Car - Orange : Toys & Games

1993 Porsche 911 964 Carrera 2 Rare 1 of 505 US Coupes/ Amazon Green /5 Speed Manual /Limited Slip Differential - RMCMiami